The F-35 production effort is led by Lockheed Martin, with Northrop Grumman and BAE Systems as principal partners. The F-35 is produced in countries that have either purchased or plan to purchase the aircraft, which includes the United States, seven partner nations as well as Foreign Military Sales buying nations. The partner nations are the United Kingdom, Italy, Netherlands, Canada, Denmark, Norway, and Australia.

Together with the F-22 Raptor, the F-35 Lightning II is the only true fifth-generation fighter aircraft, and utilizes the latest technologies within advanced aerostructures, sensor systems, electronics, and stealth capabilities.

A major global supplier to the Joint Strike Fighter

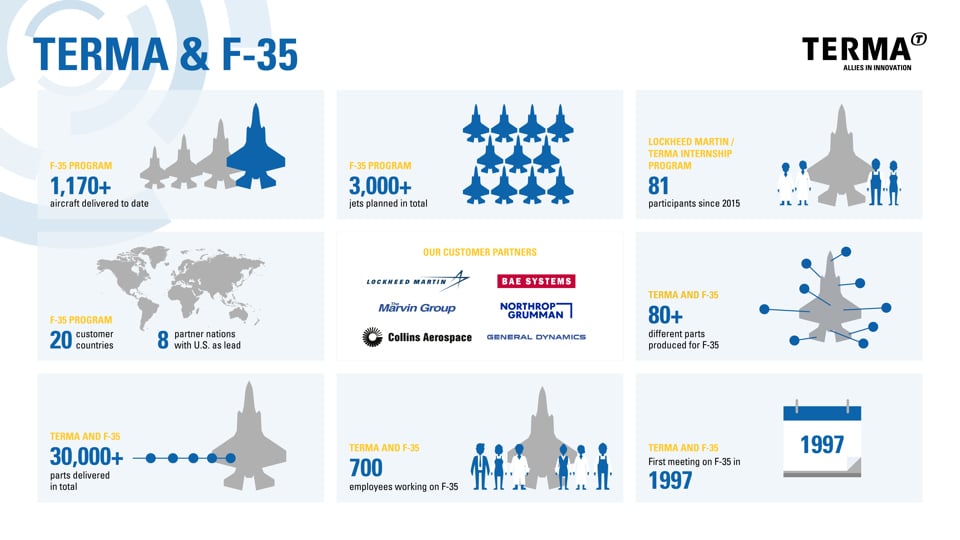

We are considered a major global supplier to the F-35 Lightning II, a role that highlights our unique position on the program. The program is based on a best value-approach, and our extensive participation is the result of our long legacy of aerostructures and electronics production and our major investments in dedicated facilities and advanced manufacturing equipment, such as large autoclaves and milling machines.

Lockheed Martin expects to manufacture more than 3,000 F-35 aircraft, a figure that could increase to as many as 5,000 aircraft over the life of the program.

Fighter competition in Denmark

Denmark is to replace its F-16 fighter aircraft by 2027. In May 2016, the Danish Government announced its recommendation of the F-35 as replacement for Denmark’s F-16s, and recommended the acquisition of 27 F-35A fighter aircraft. The recommendation was confirmed on 9 June 2016 when the Danish Ministry of Defence declared that Denmark will acquire 27 F-35As for the Royal Danish Air Force (RDAF) with delivery between 2021 and 2026. The first Danish F-35 was rolled out in 2021 and delivered to Luke Air Force Base for flight training. The first in-country delivery is on 1 October 2023 and the Danish F-35 fleet will be based at Skrydstrup Air Base. The Danish F-35 fleet is expected to be declared fully operational in 2027.

The F-35 participated in the competition to replace the aging RDAF F-16s against Boeing’s F/A-18 Super Hornet and the Eurofighter Typhoon

F-35 deliverables

Some of the more than 80+ unique parts that Terma supplies to the F-35 program:

- Composite leading edges for the aircraft's Horizontal Tails

- Composite skins for the Vertical and Horizontal Stabilizers

- Advanced lightweight composite components for the Center Fuselage

- Missionized Gun Pods for the STOVL and CV Variants

- Data Acquisition (DART) Pods for Flight Test Instrumentation

- Air-to-Ground Pylons

- Composite element rings for the F135 engine

- Radar Electronics

The Terma F-35 Timeline

October 2023

Official handover of first four F-35 to the Danish Armed Forces in Skrydstrup, Denmark

April 2021

Official Danish F-35 roll-out ceremony in Fort Worth on April 7.

March 2021

L-001, Denmark's first F-35 Lightning II production aircraft, flew its inaugural flight on March 8.

January 2021

The first Danish F-35 Lightning II rolled off Lockheed Martin’s production line in Fort Worth.

September 2019

Terma celebrates 50th anniversary as an aerostructures manufacturer and unveils composite part that will be used on the first Danish F-35 aircraft, which will come off Lockheed Martin’s assembly line in Fort Worth in 2021.

April 2019

At the 2019 F-35 Supplier Summit, Terma was awarded a Certificate of Recognition for consistently achieving green quality and delivery rating.

February 2017

Installation of a fourth autoclave (3,5 x 12 meters).

August 2016

Commissioning of the new 3,150 m2 composite aerostructures manufacturing facility, including new clean room, ply cutting area, tool storage, and offices.

June 2016

The Danish parliament decides on procure 27 F-35A aircraft.

May 2016

The Danish Government recommends the F-35 as the next fighter aircraft for Denmark

October 2015

Groundbreaking for 3,150 m2 of new buildings for the production of composite parts for the F-35 and other programs at Terma’s facility in Grenaa. The buildings house a cleanroom for layup of composite parts, ply cutting, new offices, materials rack, autoclave, and a tool storage area.

June 2015

Terma and Lockheed Martin sign F-35 Memorandum of Understanding confirming future opportunities for Terma to pursue additional component production beyond their current contracted agreements for the F-35 fighter aircraft.

September 2013

Terma’s digital X-ray equipment approved for inspection of composite parts for Lockheed Martin F-35 deliveries.

June 2013

Terma enters into F-35 Long-Term Agreement with BAE Systems for the manufacture of composite skins for all three F-35 variants.

February 2013

Terma enters into a long-term contract with Lockheed Martin Aeronautics for the manufacture of composite parts for the F-35 program.

September 2012

Terma signs a long-term contract with Northrop Grumman for the manufacture of composite components, including doors, panels, skin assembly, and straps through 2019 for all three F-35 aircraft variants.

February 2012

F-35 test team completes first external stores flight test over an Atlantic test range with external weapons pylons manufactured by Terma.

August 2010

International summer school on composites used in the international aircraft industry established at the Fuglsøcentret in Eastern Jutland.

August 2009

Memorandum of Understanding is signed by Terma and the primary partners Lockheed Martin, BAE Systems, and Northrop Grumman, making Terma a major supplier to the F-35 project program.

June 2005

Terma signs major contract for F-35 aerostructures.

October 2004

Terma signs contract for Data Acquisition Pods for Flight Test Instrumentation.

March 2004

Terma signs contract for design and development of F-35 Missionized Gun Pod.

May 2002

Denmark joins the F-35 Joint Strike Fighter program during the System Development and Demonstration (SDD) phase as a Level 3 partner.

October 2001

Lockheed Martin and Boeing present their bids for the new fighter aircraft, and Lockheed Martin's X-35 is preferred over Boeing's X-32. Terma is introduced to the project.

F-35 Dimensions

- Length: 15.37 m

- Height: 5.28 m

- Wing area: 42.7 m2

- Wingspan: 10.65 m

- Weight, loaded: 20.1 t.

- Maximal airspeed: 1,931 km/h

- Maximal G-influence: 9 g.

- Motor: 1 x Pratt & Whitney F135 afterburning turbofan

- Lift motor: 1 x Rolls-Royce Lift System, 80 kN

F-35 variants

- F-35A - the standard aircraft CTOL (Conventional Take Off and Landing)

- F-35B - equipped with STOVL technology (Short Take Off and Vertical Landing) allowing the aircraft to take off from runways no longer than 150 m and perform vertical takeoffs and landings.

- F-35C - developed as a CV (Carrier Version). This aircraft has a larger wing area, enlarged payload, and a strengthened landing gear for carrier operation.

Want to learn more?

If you have any questions about aerostructures, please get in touch with our expert.