Clarity, Flexibility and Control in Spacecraft Thermal Control

STAMP (System for Thermal Analysis, Measurement and Power Supply Control) is Terma’s proven solution for spacecraft thermal testing. With nearly 30 years of flight project experience, STAMP gives teams full control over data acquisition, heater management, and system monitoring.

All-in-one thermal test control

Scalable and configurable for any campaign

Secured remote access

Run your tests, STAMP takes care of the rest

STAMP handles the setup and management of your test facility so you can focus on running your tests. No need to write custom scripts or spend time on complex configurations, as STAMP does it for you and reduces the effort needed to prepare each test.

It’s built for flexibility: from single-device tests to full-scale spacecraft campaigns across multiple chambers. With intuitive interfaces, secure remote access, and strong integration capabilities, STAMP helps teams run tests more reliably, with less manual effort, and better collaboration across locations.

Whether you're managing ten channels or ten thousand, STAMP adapts to your workflow.

Key Technical Features

- Up to 10,000+ channels acquired simultaneously

- Real-time 2D/3D visualization and alarm tracking for quick diagnostics and interpretation

- Built-in mathematical formula for unit conversion, calibration, and data reduction

- Full logging of all system activity, values, commands, and events in a searchable archive

- Runs on Windows and UNIX/Linux

Change Configurations While Tests Run

Monitor and Present Your Data

Flexible Control of Power Supplies

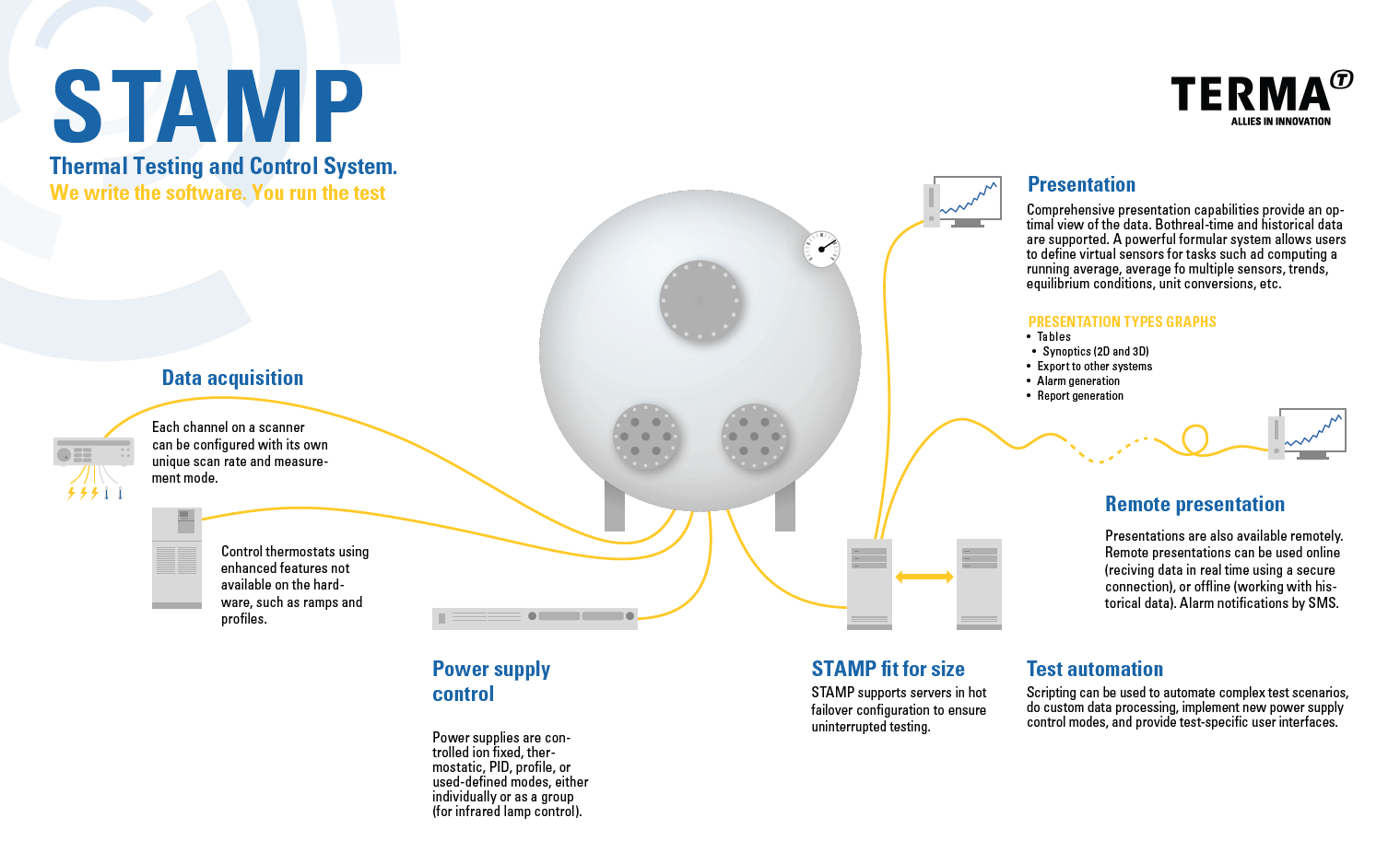

KEY CAPABILITIES OF STAMP

Unified Control and Monitoring

STAMP centralizes temperature data acquisition, hardware control and result visualization across thermal vacuum chambers. Through its modular architecture, real-time monitoring, and automated alerts, it ensures precise test execution while reducing errors and streamlining operations. The platform's intuitive interface makes it easy for new users to learn and operate.

Remote Thermal Test Viewing and Secure Collaboration

STAMP offers secure remote viewing of thermal tests worldwide. This allows engineers to monitor and respond to tests from anywhere, maintaining security and data integrity. Trusted by ESA and European aerospace industry, this feature now also helps operate more efficiently with distributed teams and fewer on-site staff.

Rapid Integration with Legacy Thermal Testing Equipment

STAMP integrates with existing hardware while preserving legacy infrastructure at facilities of our clients. Terma created seven custom drivers and used simulation tools for remote development, enabling a seamless transition that added new capabilities without disrupting operations. New drivers can be added without changing existing software.

Improved Data Transparency and Archiving

STAMP logs and archives every system action for complete traceability. With configurable outputs, intelligent logging, and automated anomaly detection, it creates a clear audit trail for analysis and compliance. This gives greater confidence in test outcomes and faster issue resolution.

Heritage

STAMP has nearly 30 years of expertise in spacecraft thermal testing. Initially developed for the European Space Agency (ESA), it has been trusted for testing spacecraft including XMM, Rosetta, ATV, MetOp, Galileo, AMS, EarthCARE, Smile, and JUICE.

Leading Space Agency Modernizes Thermal Testing

Need more details?

Then download our materials about spacecraft thermal control.

Contact us

If you have any questions about STAMP, Thermal Testing and Control System, please send us a message.

Want to learn more?

If you have any questions about STAMP, Thermal Testing and Control System, please get in touch with our expert.