Modernizing Thermal Testing with Terma’s STAMP System

By introducing STAMP, a leading space agency has adopted a powerful tool for control, data acquisition and presentation for thermal testing of spacecraft and spacecraft components.

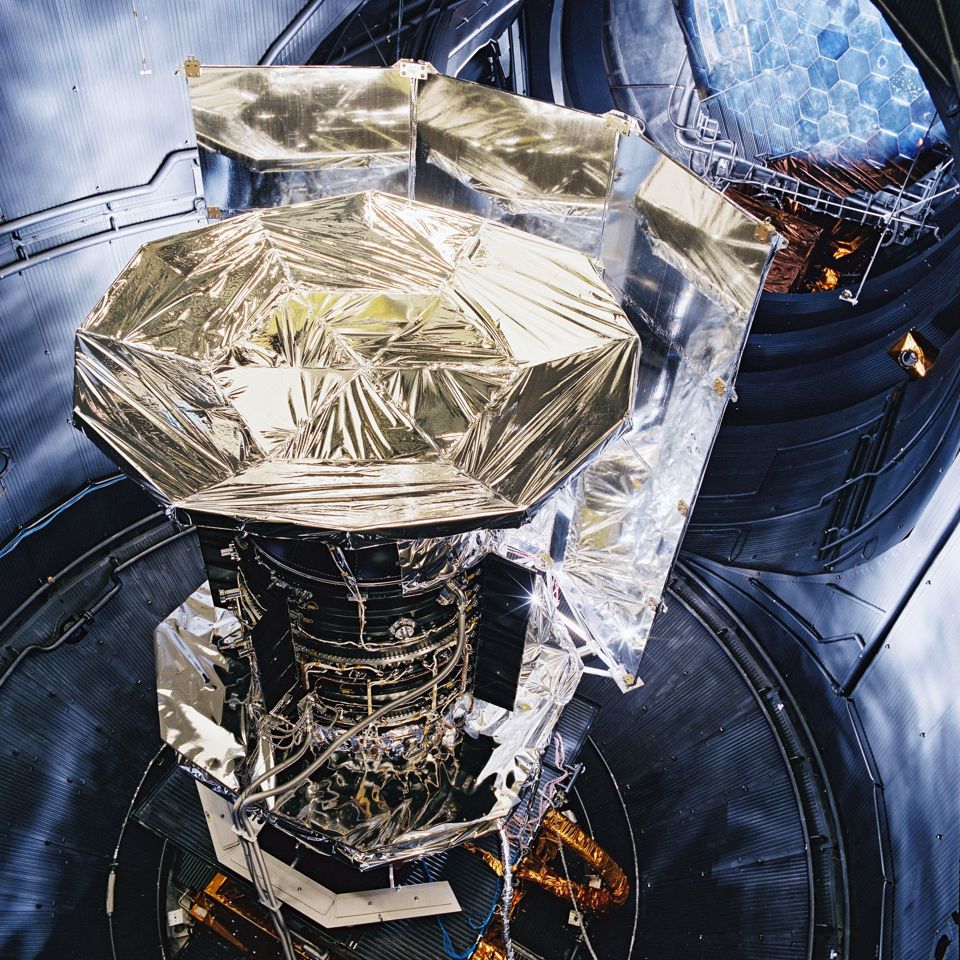

It requires uncompromising thermal vacuum testing to prepare a spacecraft for the extremes of space. Spacecraft in orbit experience thermal extremes ranging from near absolute zero to hundreds of degrees. This means robust ground validation is essential. All satellites must prove their thermal stability through rigorous thermal vacuum testing before launch.

At the leading space agency, this process was increasingly constrained by the LabVIEW systems they developed and added to over the years. The client decided to do a full software replacement, towards a system that is configurable, cyber-secure, and engineered for scale. That’s what they found in Terma’s STAMP. The team wanted a modern, flexible thermal test system. STAMP gives them the industry-standard platform.

The STAMP system

Terma’s STAMP (System for Thermal Analysis, Measurement and Power Supply Control) system brings almost three decades of experience to spacecraft thermal testing. STAMP’s key value to the client’s test centers lies in the clarity, flexibility and control it provides. STAMP consolidates hardware control, temperature acquisition, and data visualization into one unified system.

"We built STAMP to be modular, fully configurable, scalable and able to support everything from single-device tests to multi-chamber spacecraft validation campaigns."

Hans Guijt

STAMP Product Owner at Terma Space.

the Value of Stamp

To the leading space agency, STAMP introduces a new level of diagnostic traceability. Every system command, sensor reading and event is logged in a queryable archive. Previously, the client traced unexplained thermal events due to a lack of persistent logging. With STAMP, they can now account for every anomaly, every decision, down to the sensor level.

STAMP’s cyber-secure remote monitoring feature has also been particularly impactful. Teams can now observe and analyze live test data from anywhere, reducing travel requirements, boosting agility and enabling distributed collaboration.

Meanwhile, STAMP’s visualization in e.g. 2D synoptic diagrams make it easier to interpret data by linking it directly to spacecraft components.

The system has been designed to be user friendly.

"We created an intuitive interface that reduces manual intervention and standardizes processes. This way, STAMP improves test reliability, while at the same time simplifying training."

Hans Guijt

STAMP Product Owner at Terma Space

Successful Roll-out

STAMP was implemented across three test chambers, including one that had been offline for around 15 years. What began as a software deployment thus became a full operational revival.

To ensure seamless integration with the client’s test equipment, Terma developed an array of custom drivers and used simulation tools to remotely test integration before deployment. This ensured a smooth transition without interruption of ongoing projects.

The success of the roll-out positions STAMP for broader deployment at Leading Space Agency. It’s clear STAMP has the potential to support a much broader portion of their test operations. It’s the kind of system you can build a test infrastructure around.

What began as a modernization project has become a model for thermal test innovation across the space industry. In a domain where precision, resilience, and adaptability are essential, STAMP has set a new benchmark.